Before twisting, this steel wire rope will be pre -shaped in advance to process the form in the rope. Therefore, the stress of the wire rope is small and it is not easy to twist. However, after a lot of practice, it has proven that when the distance from the high rise (such as the height is greater than 100 m), the steel wire rope is not compared with the ordinary steel rope, it can only play a role in delaying the phenomenon of the wire rope. The root causes this problem.

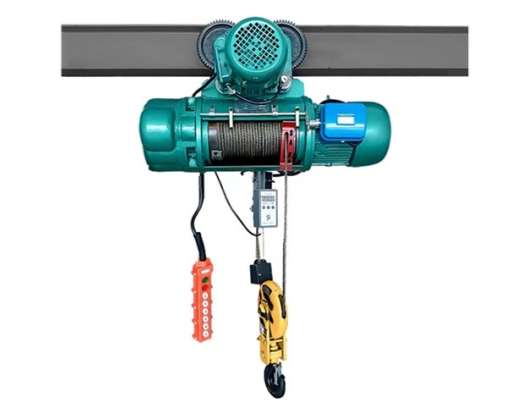

From the above analysis, it can be known that the root cause of the wire rope wrapped is that its own rotation internal force drives the hook below for rotation. For ordinary electric gourds, in order to make the wire rope neatly arranged, the rope groove is indispensable, which means that the wire rope rotation internal force cannot be eliminated. To make the hook not rotate, it can only be improved by the structure to prevent the wire rope from rotating. Pass to the hook to reach the stable effect of the hook when the wire rope is rotated, and the rotation device of the wire rope can meet this requirement well. The structure of the wire rotation device is shown in Figure 1. The upper connection axis 1 and the sleeve 2 are connected through a threaded connection, and the nail locks to form one. After the lower connection shaft 5 is put into the sleeve, it is combined with the lock mother in the sleeve. Divided into two parts, these two parts are connected through the middle thrust bearing 4. The biggest feature of this device is that due to the existence of thrust bearing, the upper and lower parts can be rotated independently, that is, when the upper connection shaft is rotated, the lower connection shaft is not moved. Essence.