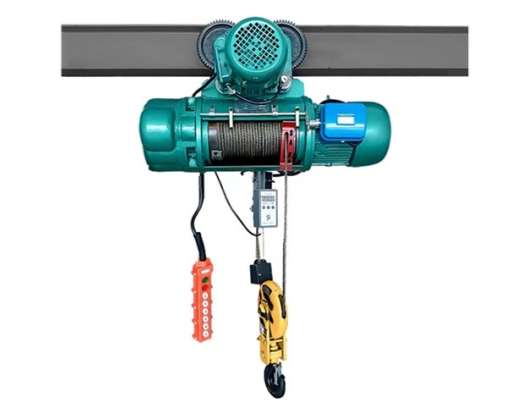

In the casting and production, a textile factory generally uses two models of electric gourds: CD and TV, but in the use, a raw steel wire rope is often squeezed into the gap between the two ends of the roll. Light squeezing the wire rope, the severe cases cause the damage of the machine to affect normal production. After repeated research on this problem, it was found that the gap between the two ends of the tube was too large, creating conditions for the squeezing of the wire rope. Therefore, a pile is welded on the inside of the two ends of the shell, so that the inner pores and the outer diameter of the rolled tube of the flange plates at both ends of the original shell are reduced from about 10 mm to about 3mm (see the figure below). As a result, the above two types of electric gourd squeezing steel wire rope is completely solved.

Improve method: First measure the gap between the inner diameter of the shell and the outer diameter of the roll and the roller and the flange plates at both ends, and process the davary according to the measured dimensions. The outer diameter of the mights is 3 one Smm smaller than the inner diameter of the shell, and the inner hole of the duty is 5 ~ 7m m larger than the curls. The thickness is generally 3 one Smm larger than the measured size. Pay attention to the thickness of the wire of the wire rope when making the pressure plate. It should not prevent the installation of the pressure plate as.

The shape of the shape of the sand casting machine is generally made of metal materials. Metal looks sometimes scratched and defects during use. It should be immediately stopped for repair to avoid affecting the quality and casting quality. Generally, welding supplement and adhesion methods are generally used for repair, but these methods are troublesome, the cost is high, and the repair cycle is longer. It takes a few hours to repair it, which will affect the normal production. Here is an introduction to a fast bonding method. This method can be repaired and used to use the damaged metal look at 3O min. Therefore, the styling machine has a short stop time, easy to operate, easy to master, low cost, good effect, and great practical value.